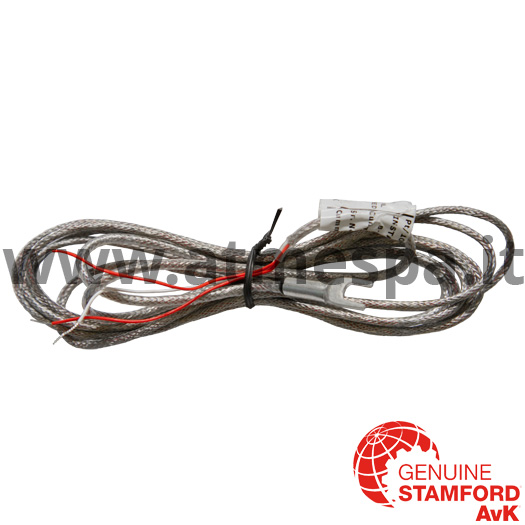

Thermistors and resistance temperature detectors (RDTs, type Pt100 as standard) are devices used to detect abnormal overheating of one or more components, which often precedes damage to the windings, so as to protect the alternator from damage. These devices have resistance values that change as their temperature changes. They are embedded within the windings or on the bearing cases to measure the temperatures at those points. The temperature devices are wired into circuits that can trip an alarm or force a shutdown of the generator if the components are overheating.

To ensure the consistent operation and long-term lifespan of your alternator it is essential you buy genuine.

Buying a genuine STAMFORD® | AvK® spare-part ensures:

- Don’t lose the validity of the alternator warranty;

- Minimised risk of plant and equipment failure;

- Maximised power supply security;

- Matched performance capability to alternator ensuring stability and responsiveness;

- A product that is tested to react in emergencies, triggering support existing protection systems.

Spare parts have a 12 month warranty.

The alternators have two types of construction form: the one bearing form and the two bearings form.

Each of these defines the type of coupling to engine, and the mode of motion transmission from the prime mover shaft to the alternator rotor.

The one bearing (built with a single bearing) are coupled to the engine via a series of discs connected to the engine flywheel. The coupling adaptor allows alignment and rigid coupling between the static engine and alternator components.

To ensure the consistent operation and long-term lifespan of your alternator it is essential you buy genuine.

Buying a genuine STAMFORD® | AvK® spare-part ensures:

- Don’t lose the validity of the alternator warranty;

- Minimised risk of plant and equipment failure;

- Maximised power supply security;

- Matched performance capability to alternator ensuring stability and responsiveness;

- A product that is tested to react in emergencies, triggering support existing protection systems.

Spare parts have a 12 month warranty.

The coupling adaptor allows alignment and rigid coupling between the static engine and alternator components.

In two bearings alternators (built with two or more bearings), the coupling between the crankshaft and the alternator shaft takes place via a rigid hub blocked onto the alternator shaft; a rubber elastic coupling is applied to the hub, which, coupled to the crown of the engine flywheel, transmits its motion. Also for this type of alternator it is necessary to install a couplong adaptor between the engine and the alternator for the correct alignment and rigid coupling of the components.

To ensure the consistent operation and long-term lifespan of your alternator it is essential you buy genuine.

Buying a genuine STAMFORD® | AvK® spare-part ensures:

- Don’t lose the validity of the alternator warranty;

- Minimised risk of plant and equipment failure;

- Maximised power supply security;

- Matched performance capability to alternator ensuring stability and responsiveness;

- A product that is tested to react in emergencies, triggering support existing protection systems.

Spare parts have a 12 month warranty.

Bearings are a critical part of generator operation. The bearings are the point of contact between the stationary generator frame and the moving rotor. There are different types of bearing used in generator construction; bearing selection is based on the application of the generator and required performances.

The bearings used by STAMFORD® | AvK® for their alternators can be divided into the following three types:

- Ball bearings, present in all the alternators of the STAMFORD® range and in the low and medium power Avk® models; they can be of the sealed type (grase-for-life) or re-greasable;

- Roller bearings, used by both STAMFORD® and AvK® in medium and high power alternators;

- Sleeve bearings, used almost exclusively for large AvK® alternators or on specific Customer’s request.

Alternator 30.000 hours / 5 years service-kits

For the 30.000 hours extended service interval the Manufacturer recommend replacing several components in order to optimise the alternator’s performance. The maintenance plan also suggests replacement every 5 years for emergency/occasional alternators.

To better optimize the maintenance activity, the Manufacturer has created these spare parts kits which include all the components it suggests replacing.

The mentioned kits are available for all the Stamford’s alternators and usually each of them includes following components:

- NDE bearing kit, including bearing, cartridge, greasing disk, grease, seals and additional fittings;

- DE bearing kit – if required – including bearing, cartridge, greasing disk, grease, seals and additional fittings;

- Rectifier service kit including diodes and one or two varistors.

To ensure the consistent operation and long-term lifespan of your alternator it is essential you buy genuine.

Buying a genuine STAMFORD® | AvK® spare-part ensures:

- Don’t lose the validity of the alternator warranty;

- Minimised risk of plant and equipment failure;

- Maximised power supply security;

- Matched performance capability to alternator ensuring stability and responsiveness;

- A product that is tested to react in emergencies, triggering support existing protection systems.

Spare parts have a 12 month warranty.

CT Droop is required when a generator must to operate in parallel with other generator(s) or the grid. Parallel droop control is a current sensing circuit that use a current transformer (CT). The droop CT output is connected to the AVR sensing supply, which is the voltage feedback signal from the main stator. The droop circuit requires a current signal connected to appropriate terminals of the AVR.

CT droop must be selected in the right way depending the model of generator and AVR and the constituent operating parameters.

To ensure the consistent operation and long-term lifespan of your alternator it is essential you buy genuine.

Buying a genuine STAMFORD® | AvK® spare-part ensures:

- Don’t lose the validity of the alternator warranty;

- Minimised risk of plant and equipment failure;

- Maximised power supply security;

- Matched performance capability to alternator ensuring stability and responsiveness;

- A product that is tested to react in emergencies, triggering support existing protection systems.

Spare parts have a 12 month warranty.